Archives

now browsing by author

Fiera Milano Xylexpo 2022: we are waiting for you

This year we will be present at the 27th world biennial of technologies, the woodworking and components fair for the furniture industry.

We will be present at the Milan Xylexpo fair

that will land from

12-15 October 2022

at the Milano Rho fair

We are pleased to invite you to our exhibition stand at the

Hall 24 STAND C17

If you need more information about MacMazza at the Xylexpo fair

Contattaci

Come and visit us and you will be able to see the operation and applications of MacMazza panel saws, we will present at Xylexpo 2022 a version of the range of flexible panel saws consisting of two panel saws mechanically joined and with state-of-the-art electronics.

Top Saw N E

|

TS V

|

|---|---|

|

|

| MacMazza has created a complete range of flexible horizontal angular panel saws Top Saw NE that strengthened by the experiences and design techniques acquired through the most advanced tools provided by the “Schneider can open” digital technology.

This version allows for mass production, doubling the production of a single blade, but also just in time production in small batches and with complex cutting schemes to optimize waste to the maximum, using two machines that can also be programmed independently. With the combination of a single blade with rear loading platform and a cross sectioning machine, also for postformed or pre-edged bars, Macmazza had already created the ancestor of this solution, called semi-automatic corner, as a more economical and compact version of the automatic corner. |

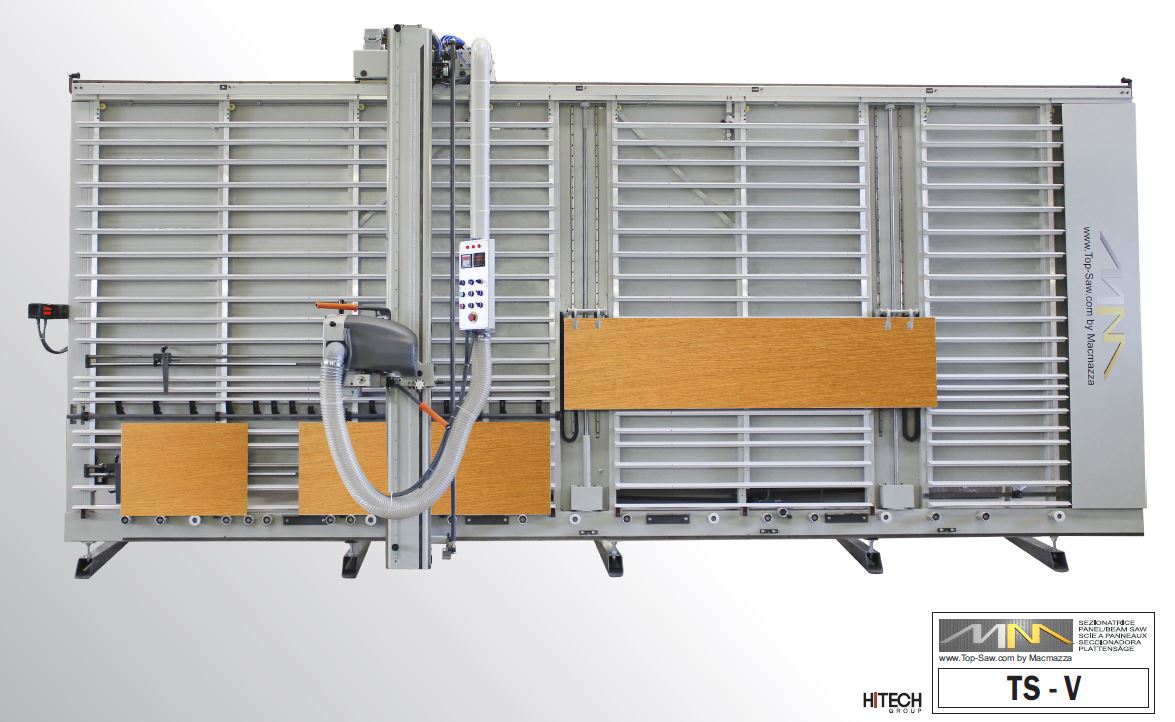

In the wide range of Macmazza products we also find the vertical panel saw TS V, with the same software and PC as the horizontal ones, therefore of top technological level and also with all the "Industry 4.0" facilities. It is equipped with pliers and blade carriage positioner to guarantee cutting precision with engraver and measurements displayed on the display, longitudinal and transversal, with a single operator. |

|

Check out the different new applications: |

|

Visit the Biennale website e read our sheet

or use the following link for pre-register

Covid Special - 19

Covid-19 emergency investigation: cutting plexiglass protections

After the new government decree, new security measures affect crowded spaces. THE plexiglass separation panels in the workplace it is one of the measures adopted on a large scale to limit exposure risks.

The material most used for the manufacture of parafiato and parasputi is transparent methacrylate plexiglas. Macmazza offers below a specific study on the cutting of plexiglass.

The cutting of the plexiglass if done with a panel saw requires a fraction of time required by the laser cutting. This confirms the technology offered by Macmazza particularly suitable for medium to high volumes.

Discover the excellent surface roughness of boron cut thanks to the help of specific blades designed for cutting plastic materials. Check out the cooling system, and an efficient system of dust extraction, which combined with a system of forward and rotation speed adjustment of the blades ensures excellent cutting quality and a minimization of blade wear and low energy consumption.

Discover technical aspects related to the panel saw by clicking HERE.

Macmazza - Productivity

F.A.Q

Produce in stock or just in time?

The answer is both

If an urgent request arrives while I have a program running?

Macmazza: No problem! Pause and then resume!

This video shows how the macmazza software has been designed to favor both just-in-time and series production. The possible scenario is shown in which an important order arrives when the horizontal panel saw is executing a list of programs. Find out how to pause the original list of programs to carry out the job and how to resume the already started production list from where it was interrupted.

If you wanted to know how long the car needs

to run a cutting program?

Macmazza: Of course yes!

Our software includes the simulator!

The simulator is a tool designed to estimate cutting times. In addition, it is a verification tool. It allows us to observe the sequence of cuts in an accelerated way. So we have a way to check the correctness of the program before running it.

Hi, How do I reduce material waste?

Macmazza: No problem!

we include the "Optimac" optimizer as standard!

With Optimac there are various interesting features made available to the user. Click on link,,en,Entry Date: September,,en,We have tried link,,it to be directed to the section where the following features are explained in detail: - Export of the optimized cutting program directly to the machine. - Management of the material rib. - Edge management. - Label printing. - Excel data import. - Customer database management. - Warehouse database management. - local or server working mode.

Customer: To avoid typing errors, you can import

cutting schemes directly from Excel sheets!

Macmazza: No problem!

Follow in the tutorial how to do it!

In this video tutorial we show how we can halve times and how we can import cutting data from a csv format

Excel.

The layout of the cut pieces?

Macmazza: Yes!

Take a look, I'll show you how.

The video presents a tool to facilitate the storage phase of the cut pieces. The pieces that can be lined up are shown in the same color.

Are there any limitations in the level of cuts included in the software?

Macmazza: No Each machine has 5 cutting levels!

In Macmazza we want every customer to take advantage of all the potential of the software. We want you to take advantage of it. We believe in this added value; from our point of view, the customer's experience and voice matters more than the sale of modules on request.

YOU CAN REALLY WORK ALONE FASTER AND CHEAPER

drive technology: a complete and flexible package

Independence thanks to the package handling Aces.

Electronics Open Source

Our local supply of spare parts from the best brands.

Macmazza delivers solutions to customer independently, including on axes movements. The saws in fact a complete mountain axes management package Turnkey Schneider signed. Discover the benefits.

standardized solution for:

- To guarantee its customers the availability of spare parts in the long-term period.

- Ensuring continuity over time and compatibility with future updates.

- Ensuring scalability: namely the possibility to combine a new system to an existing system without having communication problems or compatibility.

Why choose us

Not just quality machines,

we sell values

COMMITMENT OF ETHICS

In Macmazza build cutting ethically means to install a reliable production tool by the customer that minimizes the risk of downtime and dependence by the manufacturer. This goal is accomplished with tools self-diagnosis. These give the opportunity to client of autonomanente take action thanks to the tools that are discussed in this article.

Plastic Cutting

CUTTING OF PLASTIC

We present videos demonstrating the experience gained in cutting panels and slabs.

The advantages in the use of a panel saw reside in the superior performance (in cutting) with much less waste. Thanks to blades with a much lower thickness than the tools used in CNC machines. But above all in streamlining the work of the latter as they are used for particular processes.

We turn to us both companies that produce components even of very small dimensions, such as the insulating materials of electrical transformers or commercial displays, perhaps then processed by other numerical control machines; than companies that produce large products.

Below are videos showing the sectioning of plastic materials.

Plastic sectioning by Macmazza - TopSaw panel saw

Plastic sectioning by Macmazza - TopSaw panel saw

Links to display the panel saw used TOPSAW

The panel saw uses programs and optimization software that minimizes panel movements during the cutting cycle. The same optimization software communicates with the machine interface.

Noise control and dust extraction are of efficiency not comparable to any CNC and can be supplied in a complete and guaranteed turnkey package, testable by us with your materials that will be properly sectioned and vacuumed.

The cut materials commonly, also consisting hardnesses or with apparent problems of handling, are the plastic and composite materials of the most varied types, textures, sizes and thicknesses, for example: Corian, ant, HPL, laminate, pa6 nylon, PA66 nylon, polyethylene -p, arnite-PET, PVC, POM-acetal, teflon, ABS, polyamide polizene PTFE Zellamid, compact and alveolar polycarbonate, methacrylate, lexan, Celeron vetronite, TECNOCOL (polyurethane), peek Zellamide.

Aluminum Cutting

Saws Cutting Aluminum

In this section we present videos demonstrating the experience gained in cutting panels and slabs, for companies that produce components even of very small dimensions, such as the insulating materials of electrical transformers or commercial displays, perhaps then processed by other controlled machines. numerical, so that the CNC work can be dedicated to the drilling and / or pantographing of the case, thus greatly increasing its yields thanks to the separation of the cut entrusted to the panel saw, a machine dedicated to superior performance (in cutting) and with much less waste thanks to blades with a much lower thickness than the tools used in CNC machines.

Aluminum beam cutting with Macmazza - TOP SAW panel saw

Aluminum plate cutting with Macmazza panel saw - TS 150

aluminum plate cut with the panel saw Macmazza

Strengths:

The panel saw uses a optimization software which make possible a much lower waste than any CNC and can be interfaced with any other PC or machine software and / or with the management software.

The control noisiness ed aspiration powders are of efficiency not comparable to any CNC and can be supplied in a complete and guaranteed turnkey package, testable by us with your materials that will be properly sectioned and vacuumed.

Aluminum plate cutting with Macmazza panel saw - TOP SAW 135

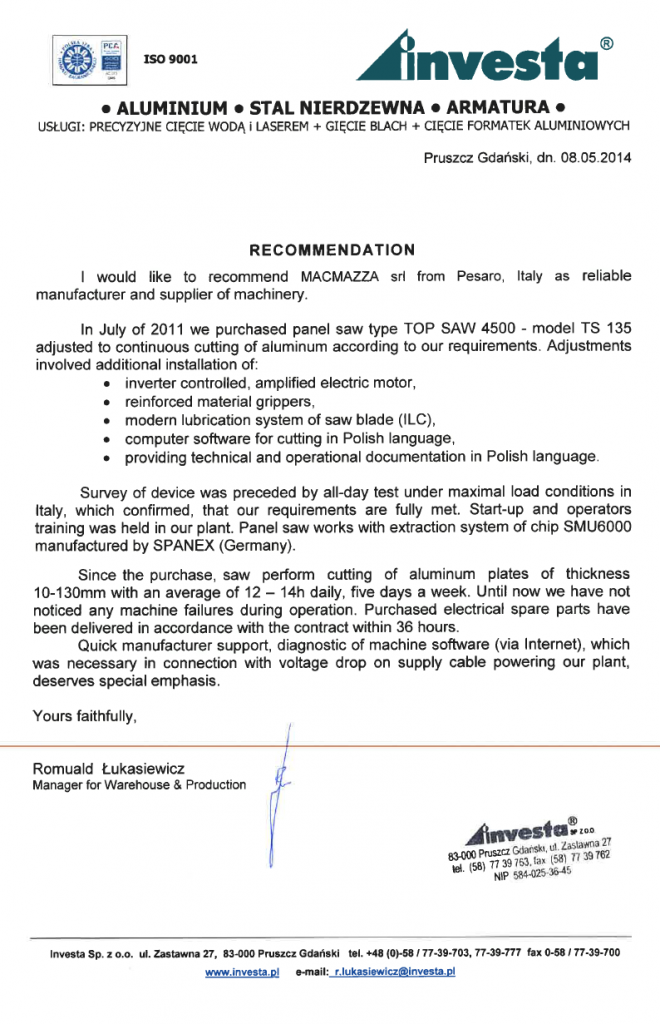

Please find below a letter of references from one of our important and expert user:

loading system of thin panels

Loading system for thin panels - Macmazza

It presents the pneumatic system designed to ensure the load pthin panels from the loading platform.

Thin panels have a high deformability. Therefore they are arranged in a non-linear fashion. This requires a system specially designed for carrying out this task. The Macmazza system uses two pneumatically operated asymmetric forks. Thanks to these, and to the movements observable in the video below, this system performs the task of loading the thin panel very well.

The sequence of movements that the forks perform can be observed in the following video.

After the panel loading phase, in the video it is possible to observe the realignment phase.

This phase is common both for cutting thin and normal panels. This phase takes place by means of the dynamic pressure between the pusher and the retractable stops. Once the panels are aligned the pusher proceeds with the sectioning phase.

Banco frontal rotating air blowing

The front air curtain rotating bench consists of a device, manually operated, designed to facilitate the manual rotation of one or more panels to be sectioned. Consisting of: a rotating frame on which a "air cushion" device lies;

Banco rotating air blowing

D5 Creation

D5 Creation